Quadrant Design Considerations

This sections contains technical information that should be considered when designing using the Quadrant system from Click.

Glazing Options

Glazing beads are available for either 6mm or 4mm material. The default specification is 6mm annealed glass: but 4mm toughened can be subsituted for reduced weight and greater safety. 6.4mm laminated glass can be used for higher security.

Plastic Sections

Glazing beads, sliding door track and flanges for hinged glass doors are in plastic, and come in dark grey or black. Grey is the default, and is supplied unless black is specifically requested.

Specification for Timber Infills

The standard thickness for timber infills is 12mm. Popular materials are melamine-faced or laminate-finished boards - but veneers, paint finishes or fabric facings can also be used.

Plinths

The standard timber plinth is 100mm high, made in 18mm ply, and finished in black laminate. The integral LF levellers provide up to 30mm of adjustment, and act as corner joints for the plinth panels.

Doors and Locks

Doors used in apertures with a width of 750mm or less are hinged; in apertures wider than 750mm, doors are sliding. All doors are lockable. Unless specified otherwise, locks for hinged doors are keyed alike to a standard pattern for which keys are available from stock. Locks for sliding doors are individually keyed.

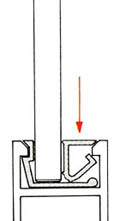

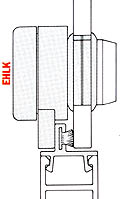

Case Lighting

Most design types allow for lighting, and either fluorescent or low-voltage tungsten is available. The fittings (see left) are designed for optimum performance in showcases, and can be ordered individually. Some cases come with lighting as standard.

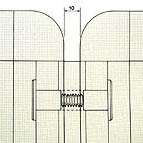

Group Combinations and Lateral Linking

The standard specifications are based on stand-alone use, with glazing on all four faces. But where units are used in groups, they may need to be joined physically together. If so, the following adaptations can be made:

- Substitute a single timber panel for the existing infills in each lateral face.

- Introduce an 18mm spacer panel to provide a 10mm gap;

- Bolt the adjacent panels together (special bolts can be supplied for this purpose).

To help visualise group dimensions, plan shapes can be drawn up with with a 300mm grid superimposed - see left. Note however that when units are linked with spacers (see above) the overall width of a group will exceed the nominal total by 10mm per junction.

Power Feed

Unless specified otherwise, the power feed for lighting is provided via 3m of cable, emerging at left back of the base. (This point is a construction detail and thus not applicable to hardware kits.)